You are here: home > Precise Effective Anodized Wire EDM Machining With Copper / Brass / Zamak

Precise Effective Anodized Wire EDM Machining With Copper / Brass / Zamak

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

GS-W-606

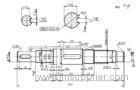

Precise Effective Anodized Wire EDM Machining With Copper / Brass / Zamak

Precise Effective Anodized Wire EDM Machining With Copper / Brass / Zamak

Quick Detail:

- Materials option includes wild steel, tool steel, aluminum alloy, copper, brass, Zamak, stainless steel, Kovar etc;

- Wide range of machines option, including low speed wire EDM, mid-speed wire EDM and high speed wire EDM, will bring you most cost effective solution but still at high quality level;

- Surface finish can be anodized, passivated, electroplating or even powder coated and many more;

- Final dimensions and other requirements fully checked by our QA people before shipping, quality guaranteed;

- Roughness and geometric tolerances etc as per the prints or even better;

- We can support your prototypes development, please contact us;

- Flatness, parallelism, perpendicularity, TIR to be 0.05mm or less.

Description:

- We have 5 low speed wire EDM from Sodick, plus 10 mid-speed and high speed wire EDM machines.

- Depending on actual requirements on precision and complexity of the parts, we can select right process for you to save cost, but no compromise on quality.

- When we decide to use wire EDM process on your parts, it means wire EDM process is the best suitable process.

- Wire EDM process can shape some small features which can’t be accomplished by CNC milling centers.

- As wire EDM machines can cut material in long distance, it is more cost effective than other processes in this case.

- Wire EDM process is commonly used in mould/tooling/fixtures construction, some small but precision parts, sheet metal parts etc.

Applications:

- Defense, auotmotive;

- Telecommunication, consumer electronics;

- Industrial equipments, medical device;

- Aerospace, oil and gas;

- Infrastructure and processing equipments, gear motors etc.

Specifications :

| 1) Material | Wild steel, tool steel, aluminum alloy, copper, brass, bronze, stainless steel, Kovar, sheet metal etc |

| 2) Finishing and Treatment | Shot blasted, anodized, electroplating, passivated, painted or powder coated, quench and temper, annealing etc |

| 3) Equipments involved | Wire EDM machines, Sodick |

| 4) Processes involved | Wire EDM cutting |

| 5) Dimensional tolerance | ±0.006mm or less |

| 6) Geometric tolerance | ±0.02mm or less |

| 7) Roughness | Ra 0.025 or less |

| 8) Production capacity | 1,000pcs per month |

| 9) Quality inspection | IQC, PQC, FQC |

| 10) Lead time | 14 days |

| 11) Place of delivery | Shenzhen, China |

Competitive advantages:

- Adhere to specification, quick response, fast delivery;

- Cost effective, quality guaranteed;

- Wide ranges of wire EDM machines to choose from;

- Comprehensive machining processes and knowledge of finishing, treatment requirements,

- Experienced people for various machining processes;

- With wire EDM machines, we can machine some parts more quickly than using CNC milling center, or even CNC milling centers can't do the job;

- PPAP for parts.

Related Search

Precise Machining

EDM Brass Wire

Brass Copper Wire

Brass Copper Wire Mesh

Brass Machining

Edm Wire Cutting Machine

More>>

Find more related products in following catalogs on Hisupplier.com

Company Info

China Horseshoes Online Market. [China (Mainland)]

Business Type:Manufacturer

City: Shenzhen

Province/State: Guangdong

Country/Region: China (Mainland)