You are here: home > Copper , Brass , Bronze CNC Milling Parts For Temperature Instruments

Copper , Brass , Bronze CNC Milling Parts For Temperature Instruments

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

GS-E-106

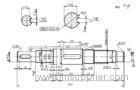

Copper , Brass , Bronze CNC Milling Parts For Temperature Instruments

Copper , Brass , Bronze CNC Milling Parts For Temperature Instruments

Quick Detail:

- Materials option includes copper, brass, alloy steel etc;

- Comprehensive machining processes CNC turning, CNC milling, boring, cylindrical grinding, Wire EDM etc;

- Milled by Victor Taichung CNC machine;

- Surface grinded or as is;

- Passivation treatment applied;

- Hardness NA;

- Roughness Ra 1.6;

- Flatness, parallelism, perpendicularity, roundness to be 0.03mm or less;

- Final dimensions and other requirements fully checked by our QA people before shipping, quality guaranteed.

Description:

- Parts are customed for customers as per requirements;

- Material option can be stainless steel, carbon steel or aluminum alloy etc;

- Major processes are CNC turning, grinding and CNC milling;

- Tight tolerances;

- Parts are hardened, tempered or anodized as per drawings;

- Dimensions and other requirements are fully checked.

Applications:

Parts are applied for:

- Defense, auotmotive, telecommunication, consumer electronics, industrial equipments;

- Medical device, aerospace, oil and gas, food and beverage processing equipments,

- Gear motors, auto vending machines, HVAC system etc.

Specifications :

| 1) Material | SS430, copper, brass, alloy steel etc |

| 2) Finishing and Treatment | Polishing, grinding, passivation, anodizing |

| 3) Equipments involved | CNC machining/milling center, CNC lathe, surface grinding machine etc |

| 4) Processes involved | CNC milling, turning, tapping, grinding, polishing, etc |

| 5) Dimensional tolerance | ±0.01mm or less |

| 6) Geometric tolerance | ±0.02mm or less |

| 7) Roughness | Ra 0.025 or less |

| 8) Production capacity | 10,000pcs per month |

| 9) Quality inspection | IQC, PQC, FQC |

| 10) Lead time | 30 days |

| 11) Place of delivery | Shenzhen, China |

Competitive advantages:

- Adhere to specification;

- Quick response, fast delivery;

- Cost effective;

- Quality inspected and guaranteed;

- Our comprehensive machining processes and knowledge of finishing, treatment requirements, tapping and insertion of heli-coils etc will end your arduous journey of looking for qualified suppliers for your custom machining needs.

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

China Horseshoes Online Market. [China (Mainland)]

Business Type:Manufacturer

City: Shenzhen

Province/State: Guangdong

Country/Region: China (Mainland)